How a single seal failure could cost you Millions

So far in the Oil Lab Series, we have covered the benefits of an on-site oil analysis laboratory, what your investment (and return thereof) could be, all the factors you need to keep in mind when building your lab, as well as Yellotec’s recommended 3 Phased Approach to set up your on-site lab.

In our last article of this series we will be looking at a case study of how an on-site laboratory and regular routine used oil analysis enabled a company to avoid a major costly failure.

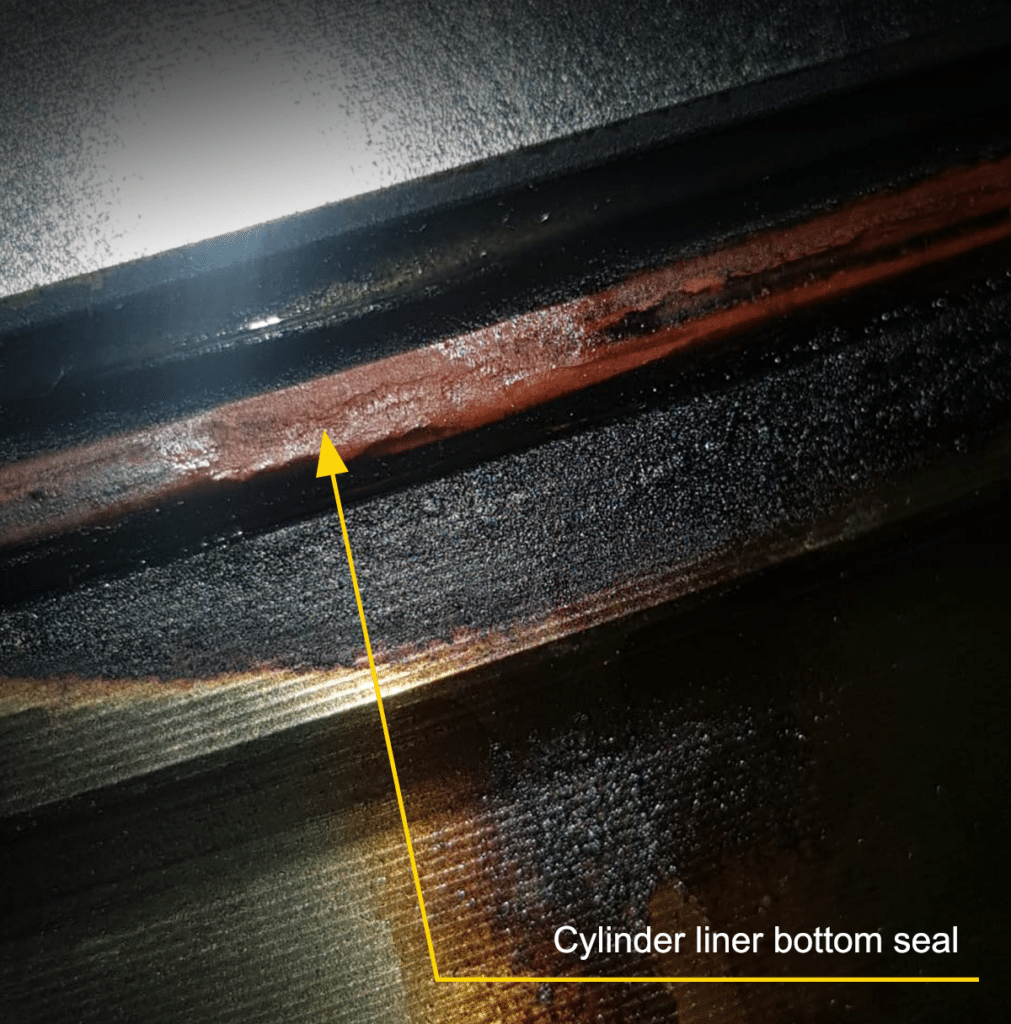

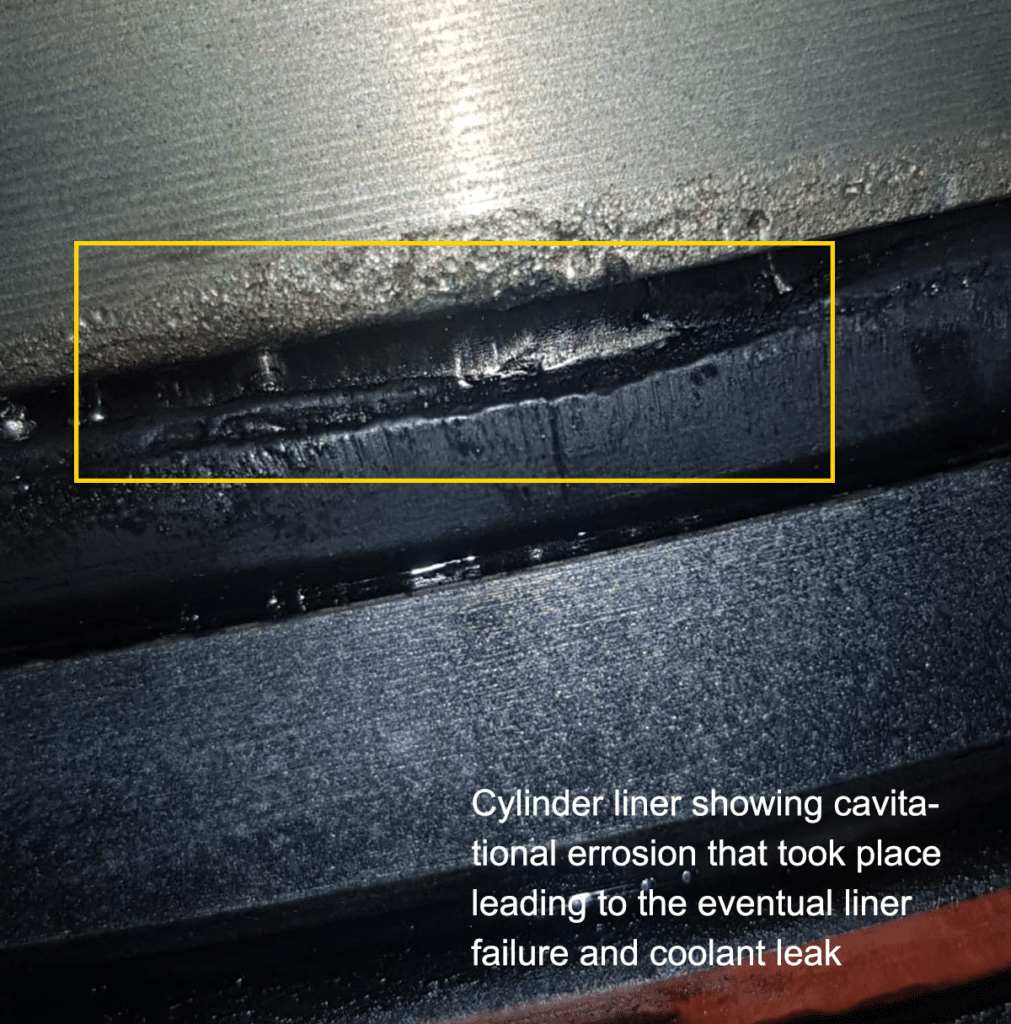

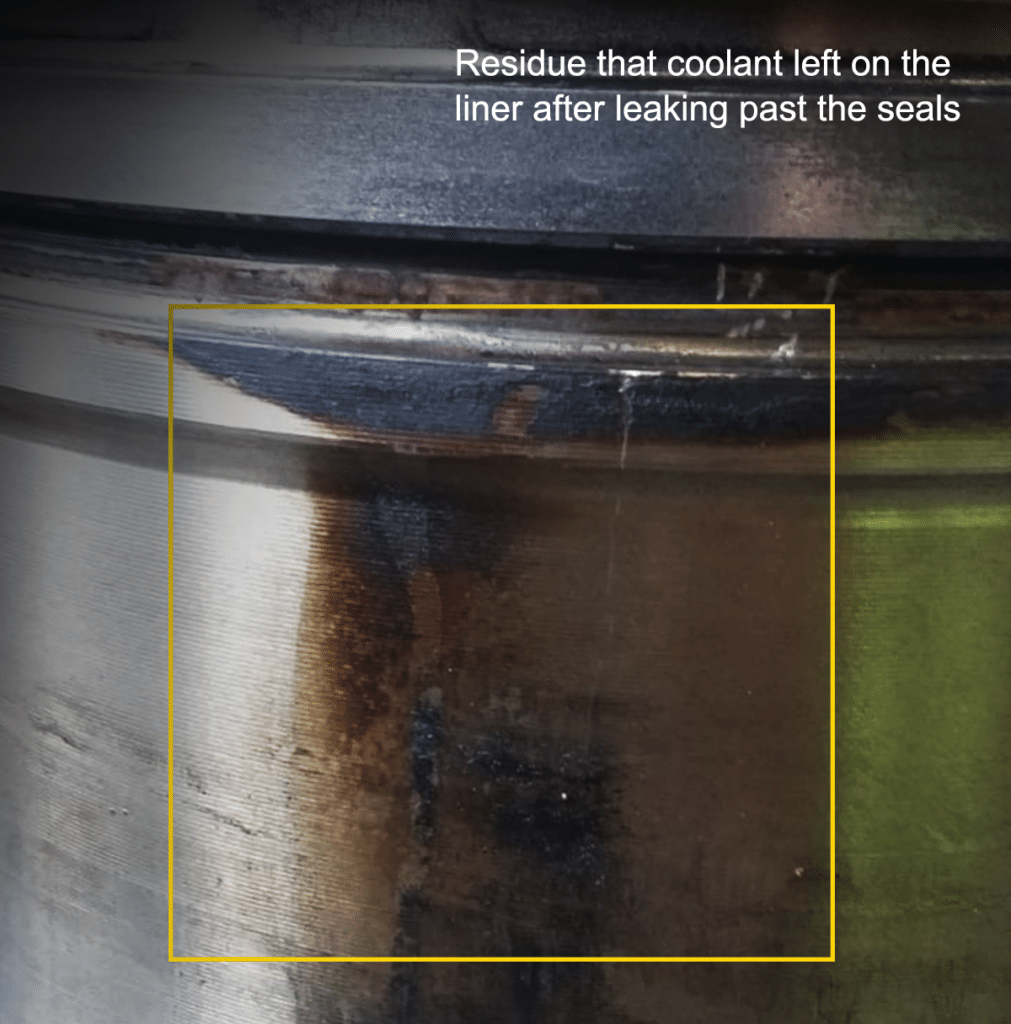

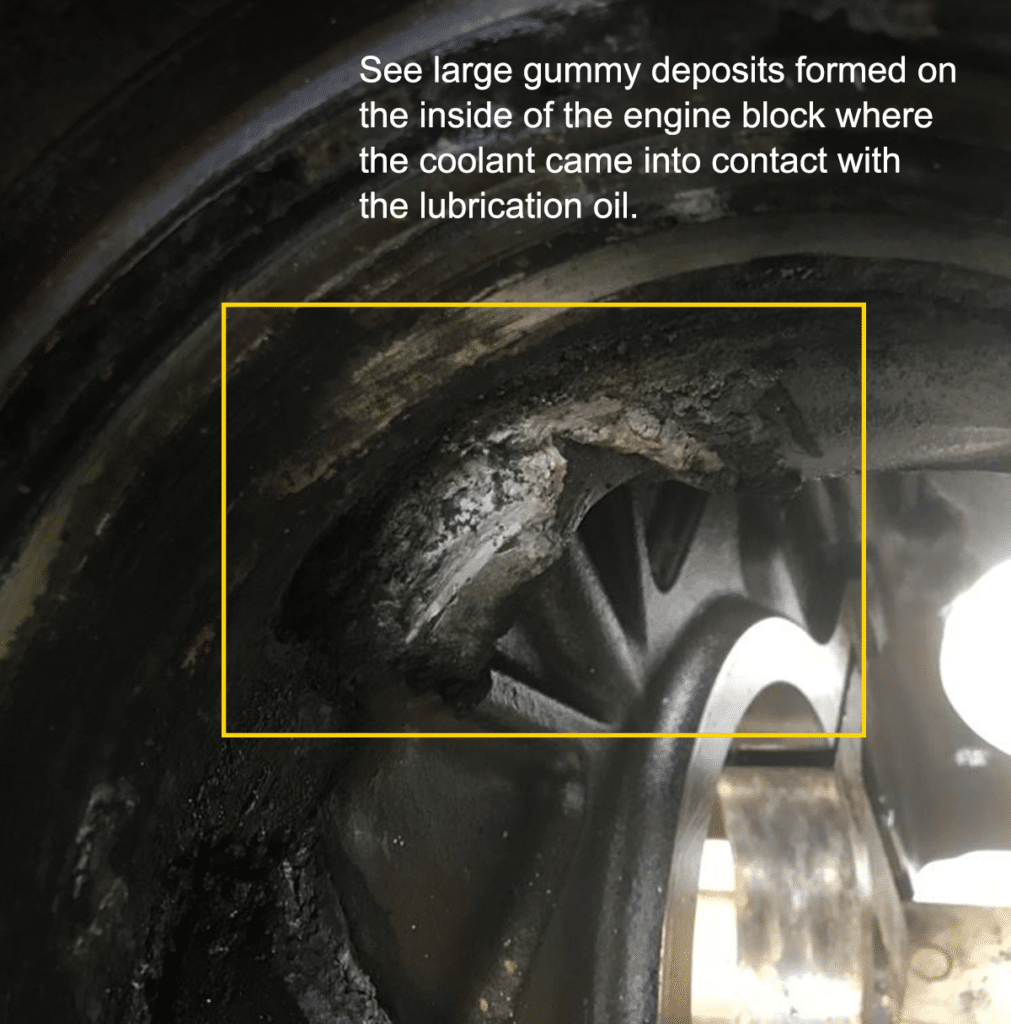

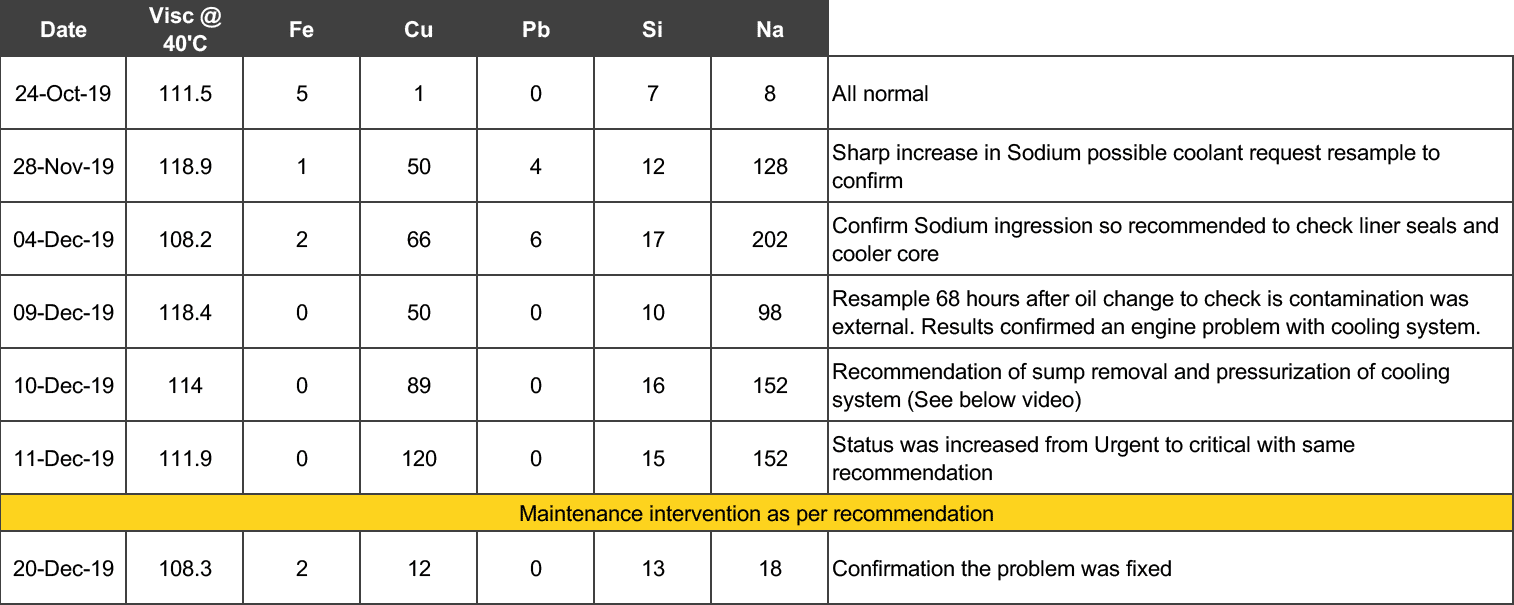

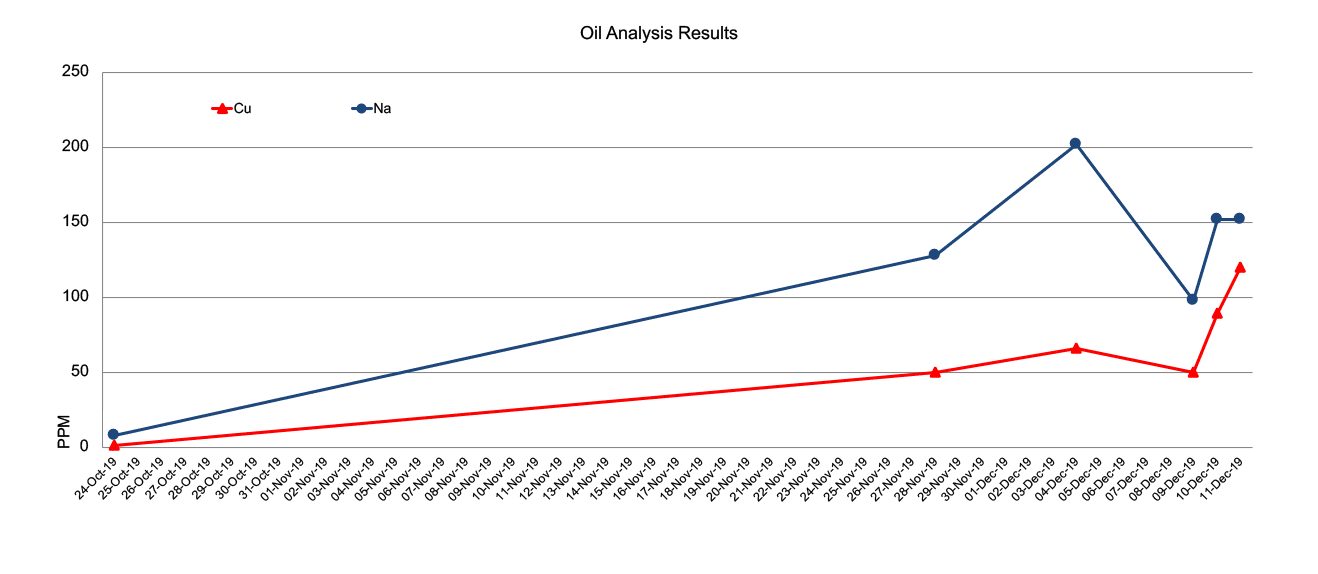

During routine used oil analysis conducted at an on site laboratory situated on an opencast mine, the lab picked up an anomaly from a dump truck engine used on the mine. The lab observed an abnormal condition whereby the sodium increased and copper wear was observed within the oil samples over time.

If this anomaly was never detected, and the dump truck engine failed because of it, the cost to rebuild the whole engine would easily have been estimated to be R 5.4 million. Luckily, early detection of the fault condition, and subsequent intervention of the maintenance department, brought the actual cost to repair the failed cylinder liner down to R63 000.

Because of the company’s ability to take daily samples and perform immediate analysis in their on-site lab, they were able to observe the results of an oil change on the health of the machine, as well as effectively take remedial action when the liner was replaced. Clearly in this case, the on-site lab’s prompt response enabled this company to save millions.

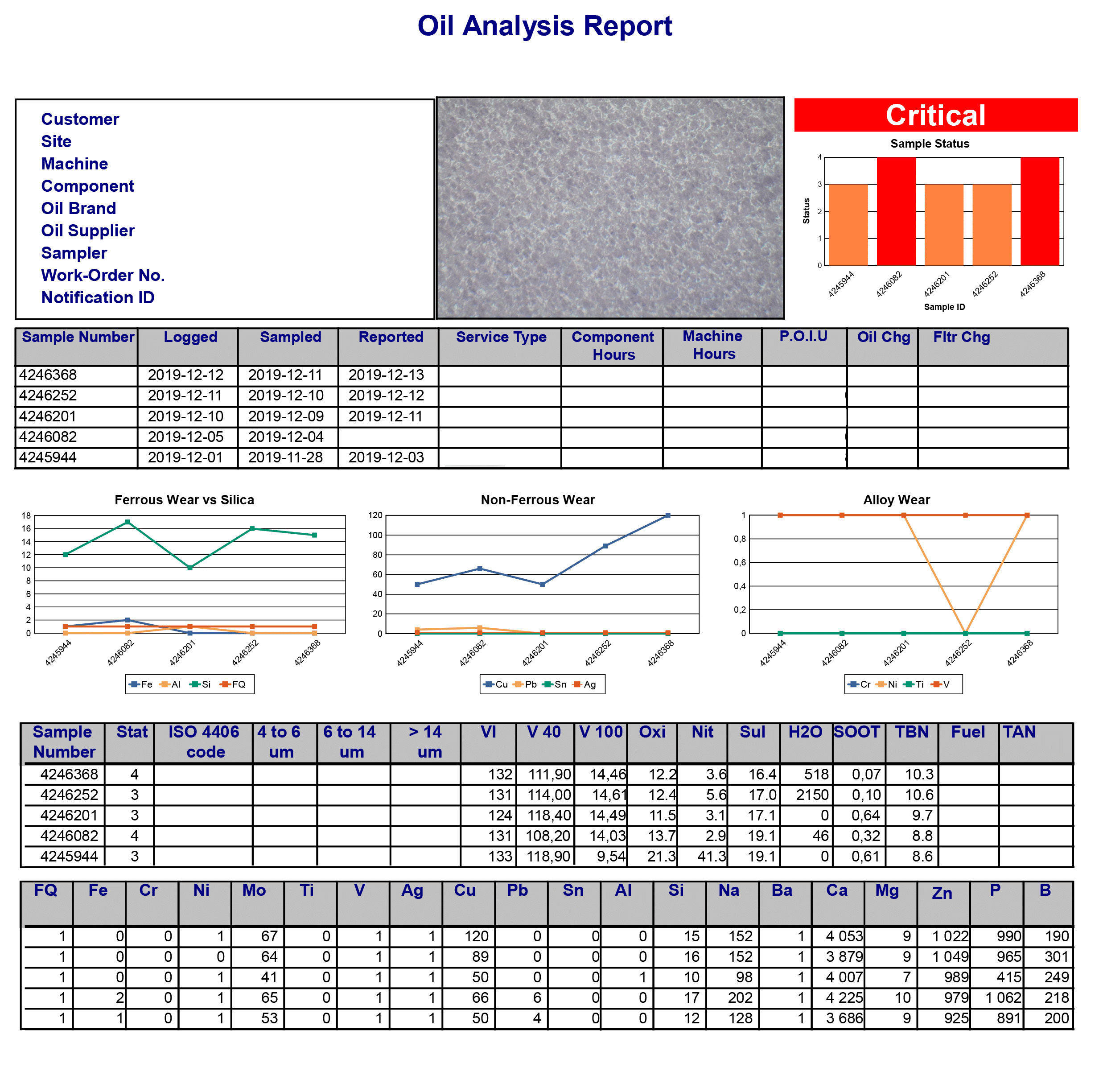

Sample data:

Report examples showcasing progression and criticality of fault.

Thank you for following the Oil Lab Series. We hope it helped to provide you with a better understanding of the benefits and possibilities of setting up your on-site oil analysis laboratory.

Don’t hesitate to contact our Specialist Oil Lubrication team for more information.